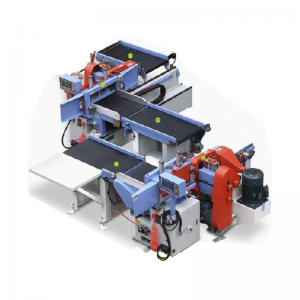

Click Floor Machine VH-M721

Device Picture

VH-M721(solid wood floor click joint)

Main Technical Data

| SPECIFICATION AND MODEL | M721 |

| working width(mm) | 25-210 |

| working thickness(mm) | 8-140 |

| Working table length(mm) | 1970 |

| Feeding speed(m/min) | 6-36 |

| Main spindle dia(mm) | Φ40 |

| Main spindle revolution (r/min) | 6500 |

| VAir pressure(MPa) | 0.6 |

| 1st LowerShaft | 5.5kw/7.5HP |

| Right vertical spindle | 5.5kw/7.5HP |

| Left vertical spindle | 5.5kw/7.5HP |

| 1st UpperShaft | 7.5kw |

| 2st UpperShaft | 7.5kw |

| 2nd Lower Shaft | 5.5kw |

| Feeding beam lifting | 5.5kw |

| Feedingmotor | 2.2x2 |

| Total power(kw) | 40.15 |

| 1st Lower Shaft(mm) | Φ125 |

| Right Vertical spindle(mm) | Φ125-Φ180 |

| Left vertical spindle(mm) | Φ125-Φ180 |

| 1st Upper Shaft(mm) | Φ125-Φ180 |

| 2nd Upper Shaft(mm) | Φ125-Φ180 |

| 2nd Lower Shaft(mm) | Φ125-Φ200 |

| Feeding wheel diameter (mm) | Φ140 |

| Dust outlet diameter(mm) | Φ140 |

| Overall Dimensions(mm) | 4300x1780x1940 |

| shuttle(kg) | 3500 |

Detail

ELECTRONIC/PNEUMATIC/CONTROL CONFIGURATION

Feed system frequency converter

Frequency number shows that the delivery speed is 6-60 meters / minute, convenient operation, reduce operation, energy saving, reduce variable speed wear.

Rapidly flip-short feeding device This mechanism effectively enhance the smooth feeding of short material, auxiliary feed wheel has a drive power to make feeding more brisk. Feeding off the wheel, easy to replace the tool and calibrated.

Precision spindle

Each spindle is assembled and tested in dust free room. SKF bearing on the double end before finished. absolutely smooth spindle ensures surface without any roughness

Front button

Add advance and retreat switch and emergency stop button in the front of the machine tool to facilitate commissioning operation and adjustment.

Heavy-cutting-resistant gearbox

The feed wheel is driven through universal joints and gearbox to ensure no loss of power.Feed delivery is very smooth, strong transmission power, high feeding accuracy.

universal joint drive

No chain of universal transmission feed, precise and strong, long service life, almost no maintenance.

Front and rear press board

The front and rear press panels can adjust the pressure respectively, even if the wood thickness changes greatly, but also can firmly press the wood on the work surface.

Double-layer panel

The left and right vertical spindle are double panels, which effectively ensure the processing verticality.

Rear discharge activity panel

The rear lower shaft panel can move freely, and various cutter are very easy to change.

Left and right click shaft

Equipped with a unique universal head cutter shaft, arbitrarily adjust the cutter shaft position according to the customer needs, to overcome at some angles, the vertical and horizontal shaft cannot be processed

Simple action panel

The operation interface is equipped with frequency conversion speed control button, digital display height of material delivery wheel, and cutter shaft start and stop

lube oil system

Equipped with independent hand shake pump lubrication table and column lifting, etc., to effectively protect the equipment for long-term use.