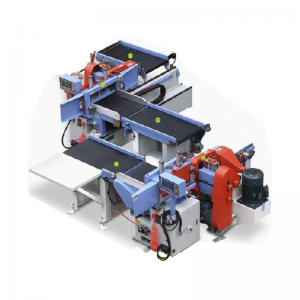

Double end tonner MX2626D

Device Picture

Main Technical Data

|

SPECIFICATION AND MODEL |

MX2626D |

|

Feeding speed (m/min) |

6-30m/min |

| Max. Working wiidth (mm) |

800mm |

| Min. Working width (mm) |

100mm |

|

Max. Working length (mm) |

2600mm |

|

Min. Working length (mm) |

300mm |

|

Max. Working thickness (mm) |

60mm |

|

Min. Working thickness (mm) |

10mm |

|

Vertical and click shaft revolution (r/min) |

6000/6000-8000r/min |

|

Vertical and click shaft diameter (mm) |

Φ40mm |

|

Vertical milling cutter diameter (mm) |

Φ160-200mm |

|

Click milling cutter diameter (mm) |

Φ180mm |

|

Feeding rubber roller diameter (mm) |

|

|

Vertical spindle motor power (kw) |

3kwx6sets |

|

Card buckle spindle motor power (kw) |

2.2kwx2sets |

|

Feeding motor power (kw) |

3kw |

|

Elevatory motor power (kw) |

0.75kw |

|

Lifting motor power (kw) |

0.75kw (width openning motor) |

|

Total power (kw) |

26.9kw |

|

Air pressure (MPa) |

0.6MPa |

|

Physcial dimension (mm) |

3450x2600x1670mm |

Detail

ELECTRONIC/PNEUMATIC/CONTROL CONFIGURATION

Feed system frequency converter

Frequency number shows that the delivery speed is 6-60 meters / minute, convenient operation, reduce operation, energy saving, reduce variable speed wear.

The elements adopt imported PLC and frequency conversion control to ensure the machine steady

Precision spindle

Each spindle is assembled and tested in dust free room. SKF bearing on the double end before finished. absolutely smooth spindle ensures surface without any roughness

Use pressed plate compression, super hard auxiliary workbench to ensure accurate machining.

Tracks (rolling bearing) with a clean brush, guide rail inlaid with super hard material, extended the machine

Service life of the device.

Width is adjusted with high precision ball screw

Magnetic gate ruler display control precision broadening

Track belt is longer, suitable for long plate processing, stability highly active.

Synchronous motor output, strong and powerful