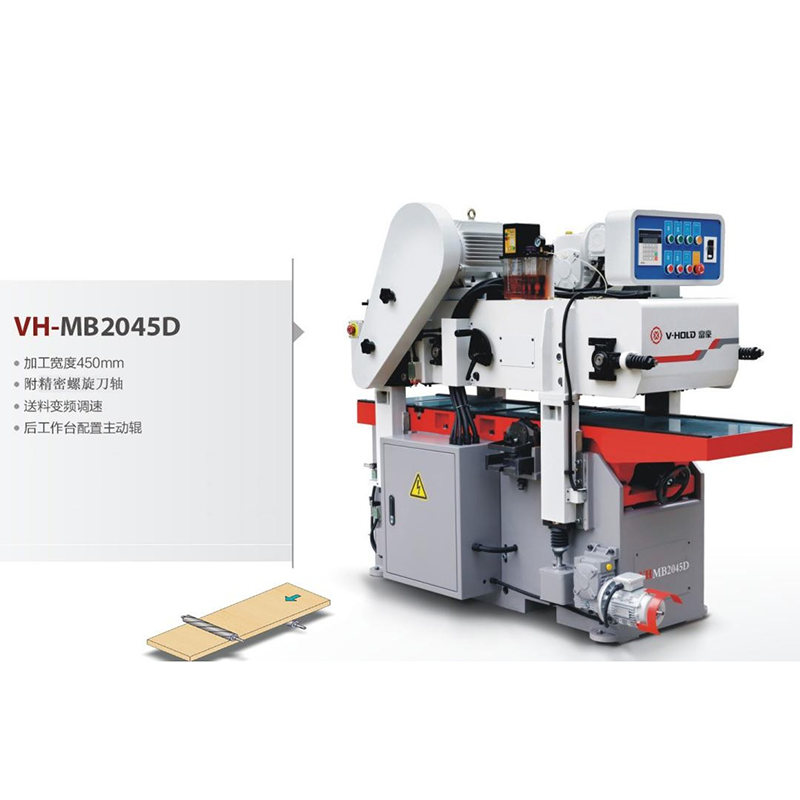

Double side planer VH-MB2045D

Device Picture

Main Technical Data

|

Model parameters |

VH-MB2045D |

|

Max.working width (mm) |

450 |

|

Max.working thickness (mm) |

150 |

|

Min.working thickness(mm) |

15 |

|

Min.working length(mm) |

320 |

|

Spindle rotation(mm) |

4500 |

|

Speed with inverter(mm) |

5~16 |

|

Spindle diameter(mm) |

∮110 |

|

Top cutter motor(mm) |

7.5 |

|

Bottom cutter motor(mm) |

5.5 |

|

Feed motor power(kw) |

2.2 |

|

Lifting motor power(kw) |

0.37 |

|

Total motor power(kw) |

15.57 |

|

Dimension(LXWXH) |

2280x1260x1680 |

|

Weight(kg) |

1850 |

Detail

ELECTRONIC/PNEUMATIC/CONTROL CONFIGURATION

Feeding frequency converter

Digital display, convenient operation, reduce, energy saving, reduce mechanical variable speed wear

Centralized oil feed system

The machine is equipped with a centralized oil feeding system to facilitate the maintenance and lubrication of each lifting system

(MB2063 is standard configuration, others are optional configuration)

electric lubrication device

Automatic oiling device can ensure that the machine is always in a state of lubrication when working.

Alarm detector, when the feed chain overload or fall off, the alarm switch will give a signal to alarm。

(2063, 2045 standard)

feeding mechanism is equipped with clutch, can prevent overload, to ensure the safe use of the machine.

(2063, 2045 standard).

Quick thickness setting. Simply place the preset thickness wood on the micro switch to make simple thickness setting.

(MB2063 is standard, others are optional)

Magnetic gate induction switch, magnetic gate transfer for thickness display

Sensor, the accuracy is much higher than the traditional proximity sensor.

The product is equipped with imported digital display device, which can be operated in

The processing thickness is directly operated on the panel, the accuracy is up to 0.05mm;At the same time, the upper and lower planing motor is equipped with an ammeter, which is very intuitive to observe the work

Is overloaded when.(optional)

Rear operation box, machine response abnormal emergency stop

Stop, or only stop and start feeding.

Processing Technic

Machine body has h high rigidity integrated

Machine body Was made of cast iron with shock absorption properties

Ensure smooth operation of cutter shaft and feed system.

Sophisticated pressing equipment

Meticulous production, to ensure that every part is nearly perfect

Japanese brand Four axis linkage machining center

All shaft frame, reducer and other accessories, the company is equipped with its own machining center processing, to ensure precision accessories

Main spindle with dynamic balance test

Each spindle is tested for movement balance. Equipped with imported SKF bearing to ensure high precision and smooth operation of the cutter shaft

Qualification