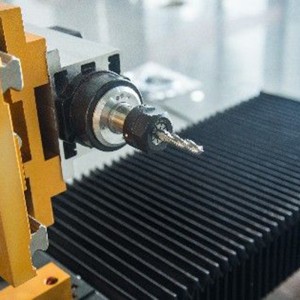

Edge Banding Machine Side Punching Assembly

Existing Processing Methods

"One Side Hole and Operator Annual input labor cost of $61,000 per month"

"Three Processes Opening > Sealing > Side Hole

Side hole operation occupies a large area." Side-hole machine and plate storage area occupies about 100 meters.

"Waste of logistics due to multiple handling Opening>Sealing>Side hole"

magnetic levitation

"√Save one operator

√ Save labor cost 60,000/year"

"√ Two processes, streamline one process, 30% increase in efficiency

√ Cutting > Sealing"

"√ Sealing edge and punching at the same time

√ Save 100m of plant area, save 10,000RMB/year."

"√ Reduce transportation waste by 50%

√Continuous flow operation, reduce defective and wrong boards caused by spreading, improve product quality."

Product Parameter

| Machine specification | Spindle motor power | No-load speed | Machining accuracy | Working air pressure | Working Stroke |

| 1400*450*650mm | 2.2kw | 120m/min | 0.2mm | 0.6-0.8Mpa | 850mm |

| 500*450*650mm | 2.2kw | 120m/min | 0.2mm | 0.6-0.BMoa | 260mm |