Floor Machine VH-M283A

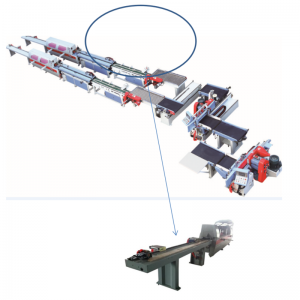

Device Picture

Main Technical Data

|

SPECIFICATION AND MODEL |

MB283A |

|

Max.working width(mm) |

300 |

|

Min.working width (mm) |

60 |

|

Max.working length(mm) |

2400 |

|

Min.working length (mm) |

600 |

|

Feeding speed(m/min) |

8-50 |

|

Vertical and click shaft revolution (r/min) |

6000-8000 |

|

Vertical and click shaft diameter (mm) |

Φ40 |

|

Vertical milling cutter diameter (mm) |

Φ160-200 |

|

Click milling cutter diameter (mm) |

Φ180 |

|

Feeding rubber roller diameter (mm) |

Φ180x12units |

|

Vertical spindle motor power (kw) |

4kwx4sets 3kwx2sets |

|

Card buckle spindle motor power (kw) |

2.2kwx2sets |

|

Feeding motor power (kw) |

5.5 |

|

Elevatory motor power (kw) |

0.75 |

|

Lifting motor power (kw) |

0.75 |

|

Total power(kw) |

35.4 |

|

Air pressure(MPa) |

0.6 |

|

Dimension(mm) |

4880x1760x1810 |

|

Net weight(kg) |

4000 |

Detail

ELECTRONIC/PNEUMATIC/CONTROL CONFIGURATION

Feed system frequency converter

Frequency number shows that the delivery speed is 6-60 meters / minute, convenient operation, reduce operation, energy saving, reduce variable speed wear.

Front workbench conveying system

Equipped with conveyor belt and independent material warehouse, to realize automatic feeding, reduce the labor intensity of workers.

Precision spindle

Each cutter shaft is assembled and tested in the air-conditioning room.Both ends are supported by imported SKF bearing and absolutely smooth cutter shaft ensures the finish surface cleanliness.

Front button

Add advance and retreat switch and emergency stop button in the front of the machine tool to facilitate commissioning operation and adjustment.

Heavy-cutting-resistant gearbox

The feed wheel is driven through universal joints and gearbox to ensure no loss of power.Feed delivery is very smooth, strong transmission power, high feeding accuracy.

universal joint drive

No chain of universal transmission feed, precise and strong, long service life, almost no maintenance.

Large feed wheel

Standard with an external diameter of 180mm large rubber wheel, effectively improve the feeding stability and line speed improvement, to achieve 60m/min material delivery.

Paneled with a solid carbide

The worktop is inlaid with super carbide to ensure wear resistance and better heat dissipation during high-speed machining.

Left and right belt tilt axis function

The shaft at the end of the left and right vertical shaft adopts a unique universal head knife shaft to adjust the position of the knife shaft according to customer needs to realize buckle processing.